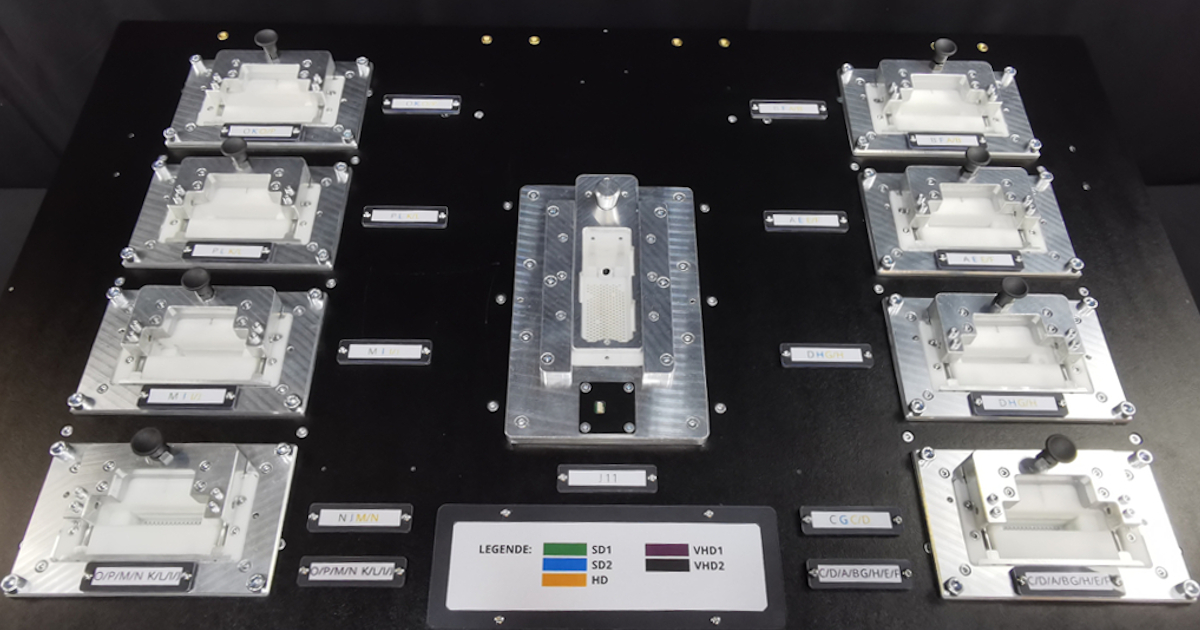

FCT test fixture for pre-assembled wiring harnesses

Customized design

The design and implementation deviate from conventional standard solutions. The test fixture was custom developed and manufactured according to the specific specifications and requirements of the customer.

Requirement

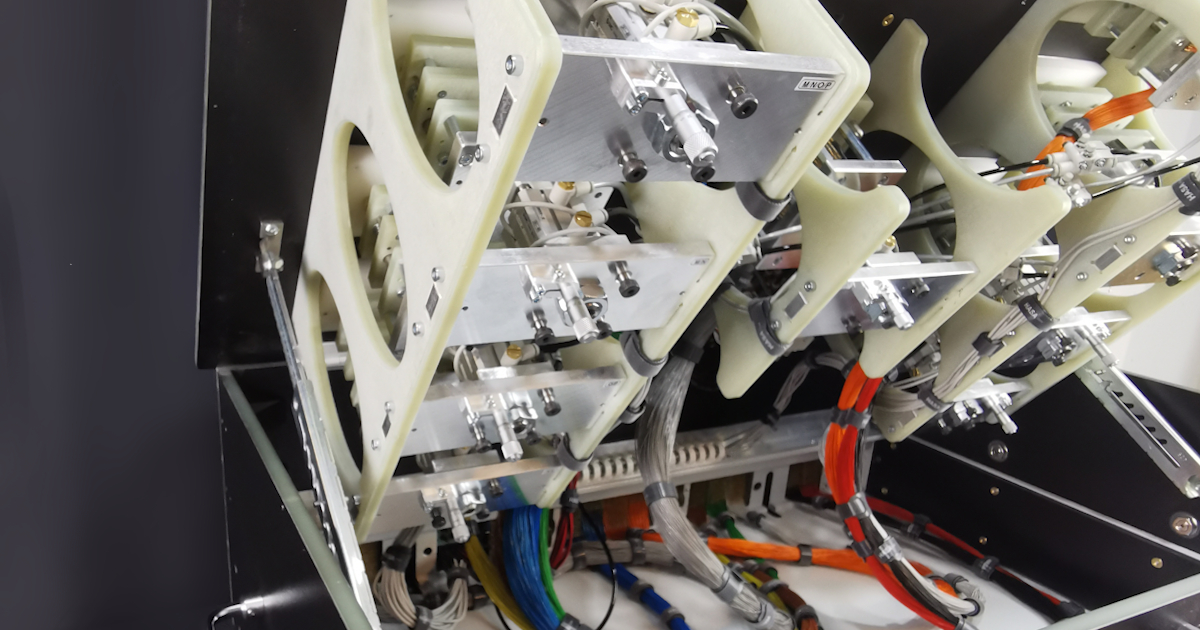

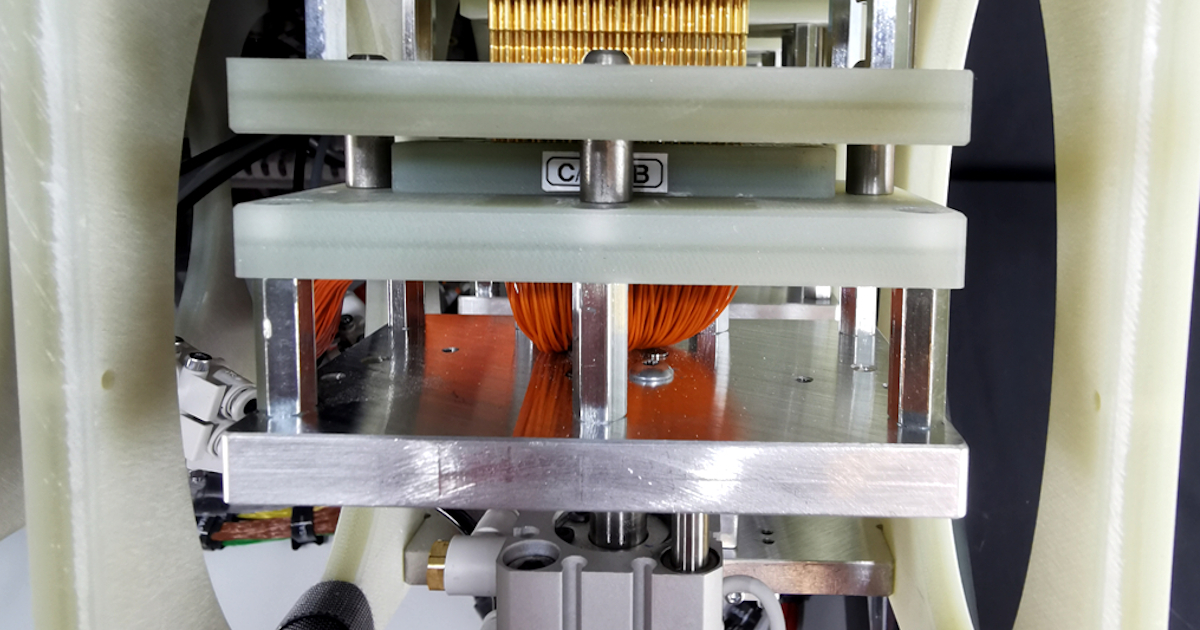

The project placed high demands on precision and flexibility. The goal was to develop an adapter for testing the functionality of cable assemblies at voltages exceeding 250 volts. A key challenge was to prevent electrical arcing in the tight grid. This was successfully achieved through the use of specialized materials and precise construction methods. The testing of connector contacts in various pressure variants was carried out using innovative technologies that ensured accurate and reliable measurements.

Solution

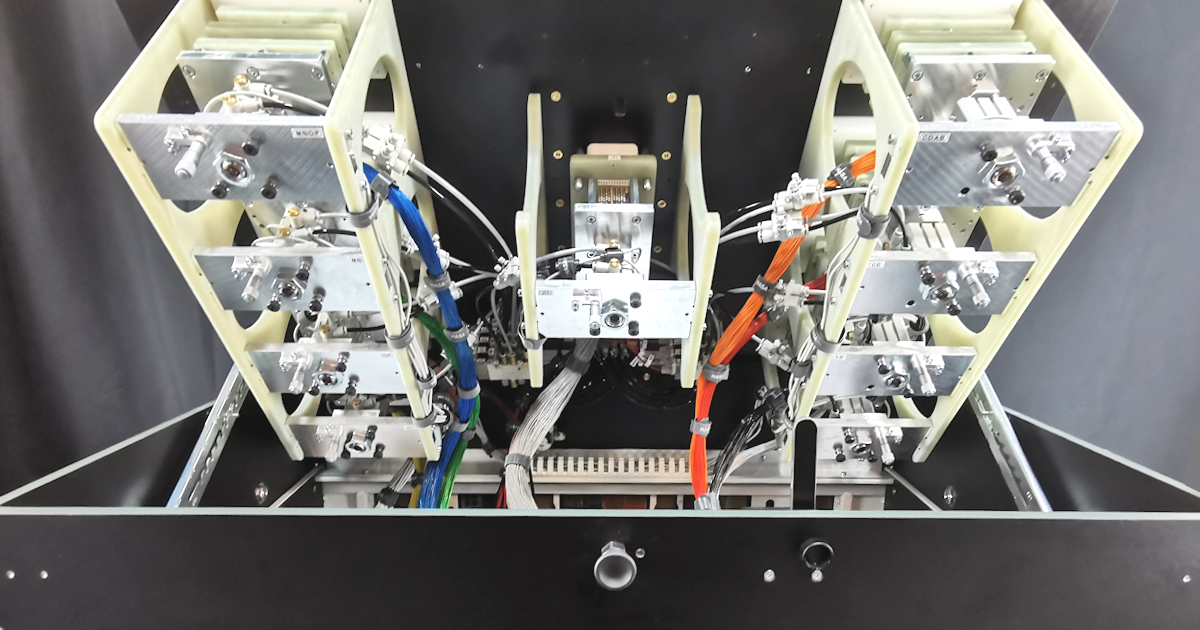

The fixturesolution consists of individually adjustable nests that allow height adjustments to test cable assemblies in different test areas. The design offers maximum flexibility, as the nests are interchangeable and accommodate a wide variety of cable harness types and series. This enables each test system to be quickly and easily adapted to new requirements. A particularly significant advantage of this solution is that the nest exchange can take place during production, significantly minimizing downtime and ensuring efficient use of production resources. Additionally, the pneumatic contact system ensures a reliable and precise connection.

Result

With eight nests, a fixed main nest, and a very fine pitch distance of just 1.4 mm, a solution was developed that not only meets all technical requirements but also offers the highest flexibility and ease of maintenance. The success of this project highlights the importance of a comprehensive understanding of the specific customer requirements. Through a precise analysis of the technical needs and a close, collaborative exchange with the customer, a customized and well-thought-out product was created.

Facts

Functional test at over 250 volts

Pneumatic contacting

Feature: Tight pitch, high variance in terms of type/series

Fixture type: Custom design

Test type: FCT