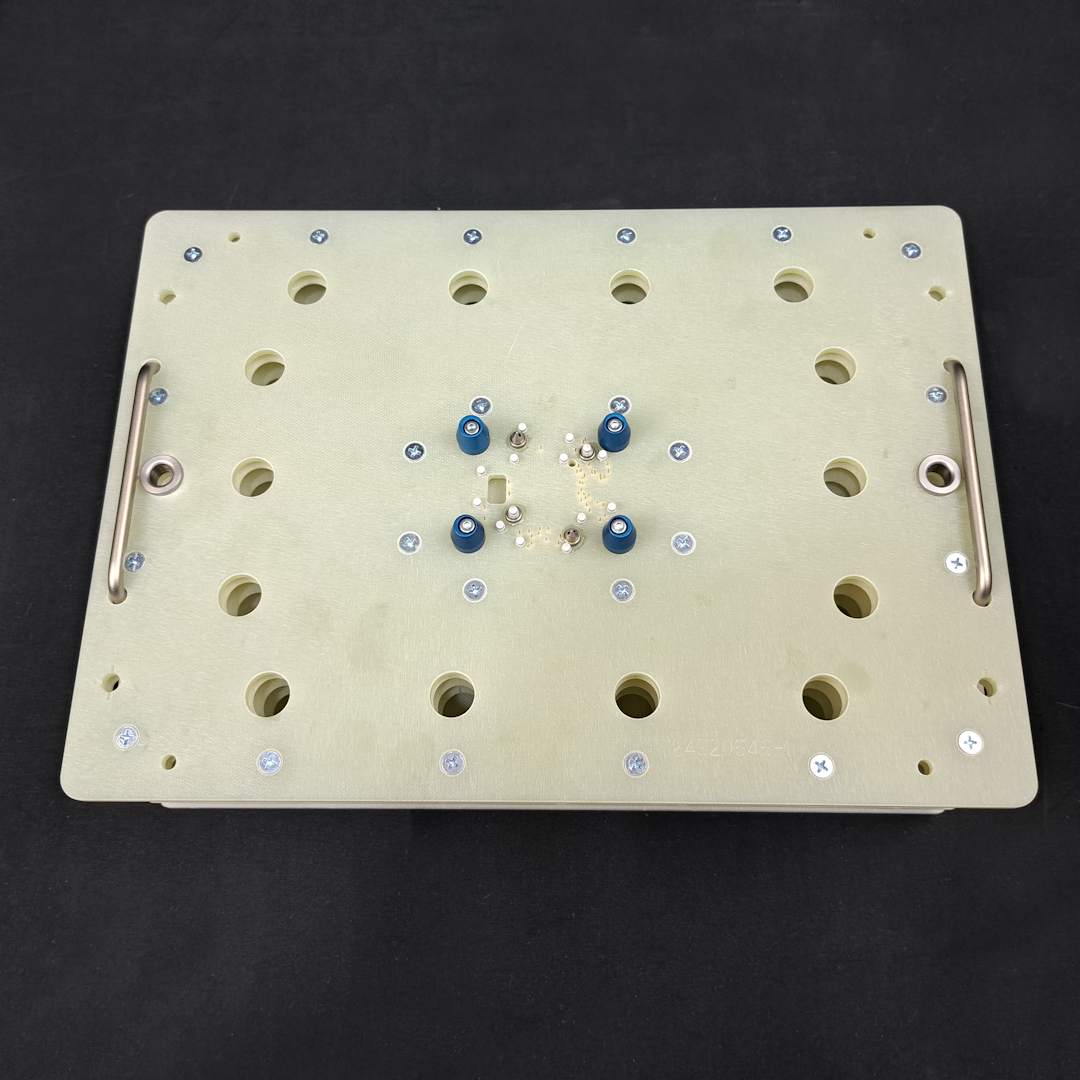

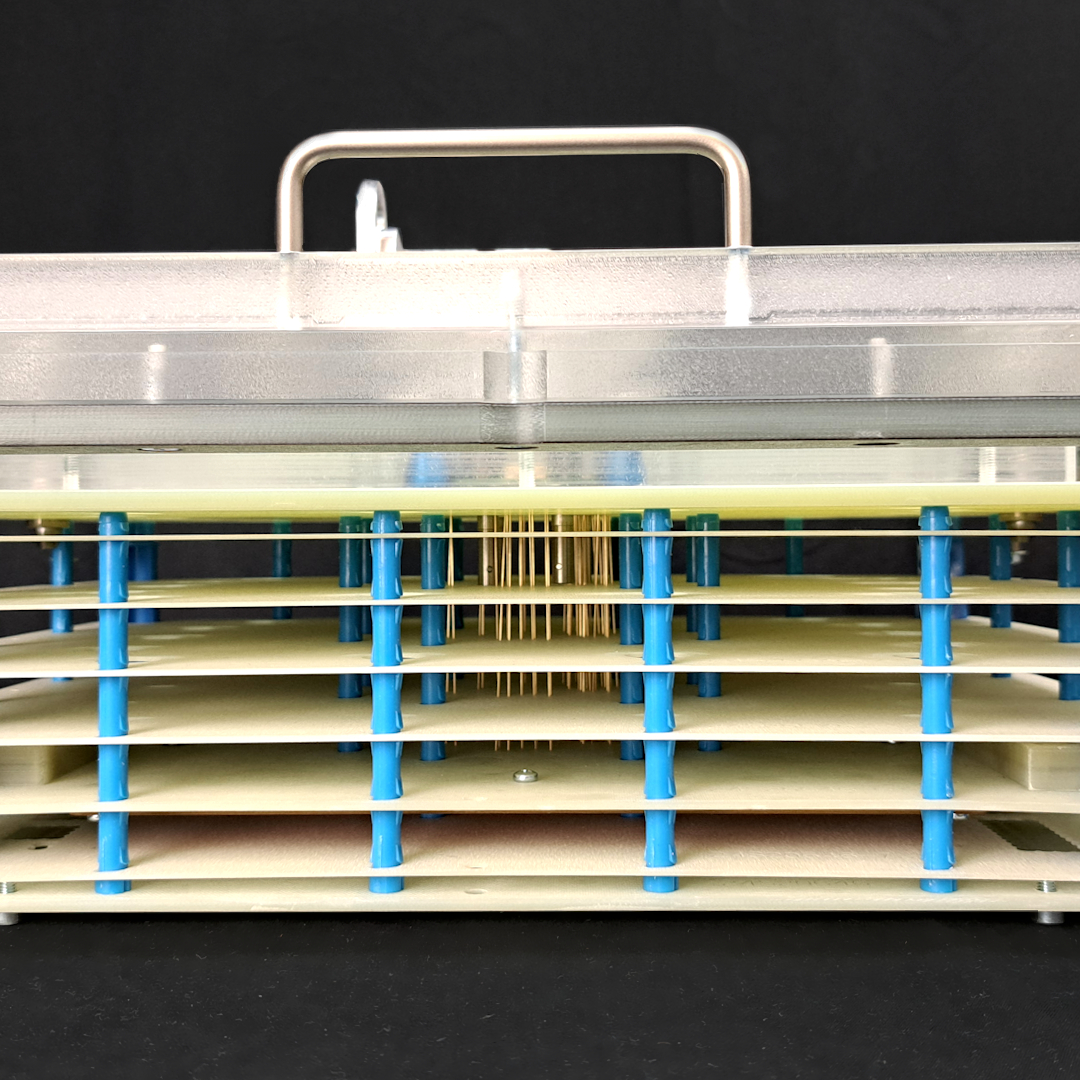

Vacuum test fixture with rigid pin Interchangeable kit

Fine pitch test fixture

The design and implementation are fully customized, not following any standard solution. The vacuum fixture, equipped with a rigid pin cassette, was developed and manufactured to meet the customer’s specific requirements and specifications.

Requirements

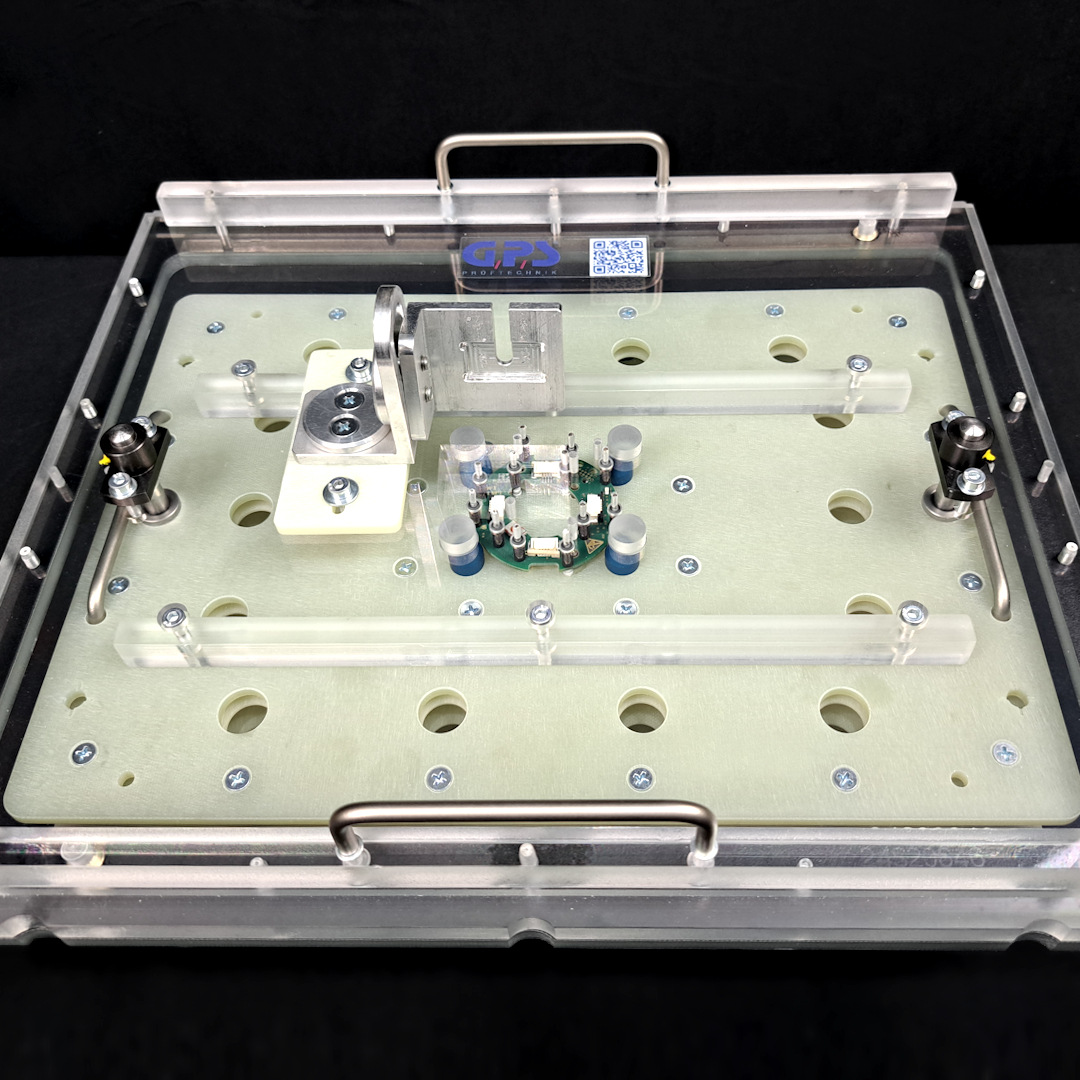

Following the customer's specific requirements, a custom rigid pin interchangeable cassette was developed to be used with a base unit. The goal of the project was to create a vacuum fixture that could be used for both ICT (In-Circuit Testing) and FCT (Functional Testing) of printed circuit boards (PCBs), while offering maximum flexibility and reusability. The need for a very tight pitch made the use of rigid pin technology essential.

Solution

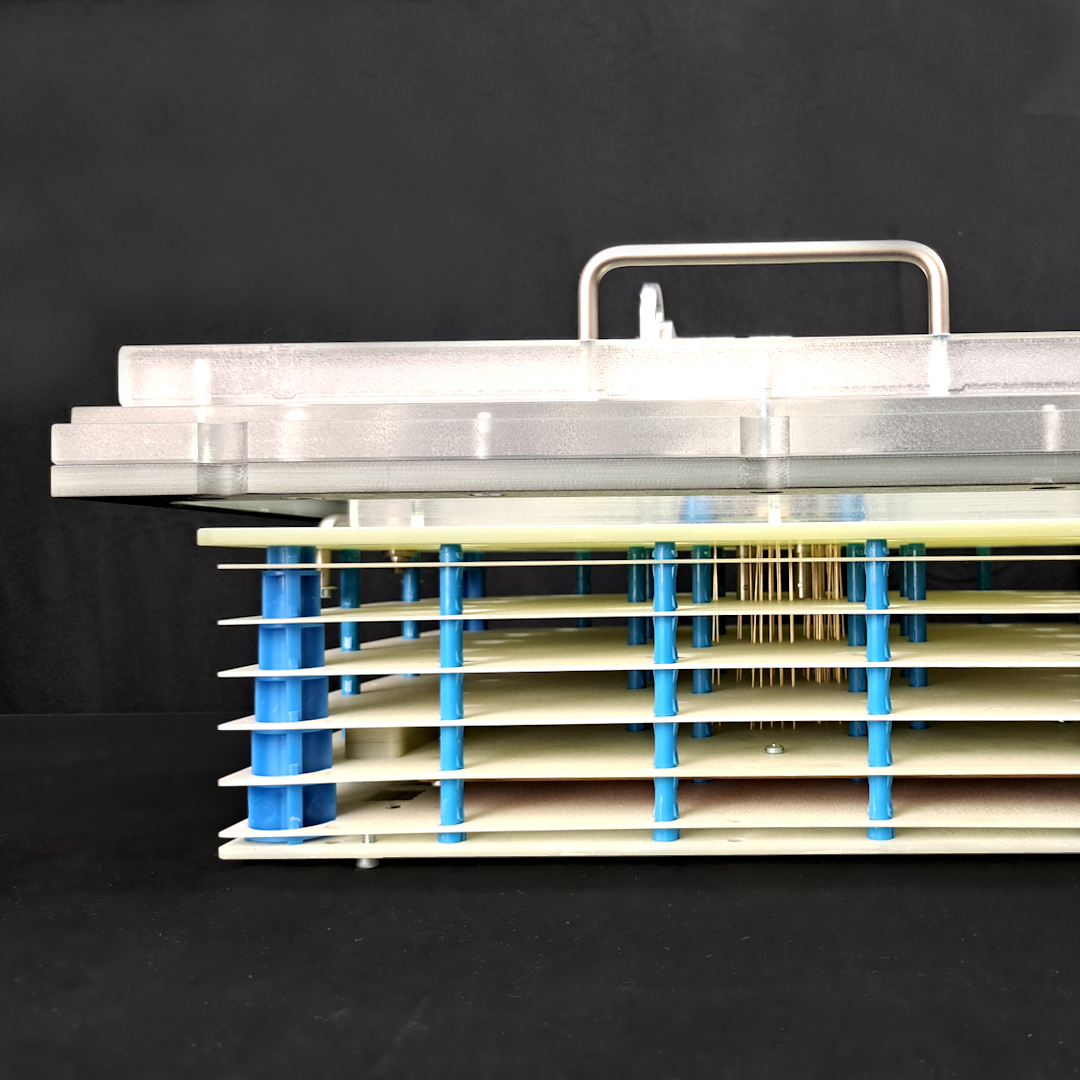

The vacuum fixture was combined with a special rigid pin cassette, enabling multiple uses of the fixture. The base unit can now be equipped with different interchangeable cassettes to test various printed circuit boards for different tests, without needing to replace the fixture each time. his modular approach saves both time and costs, ensuring efficient use of the testing station.

Technical details

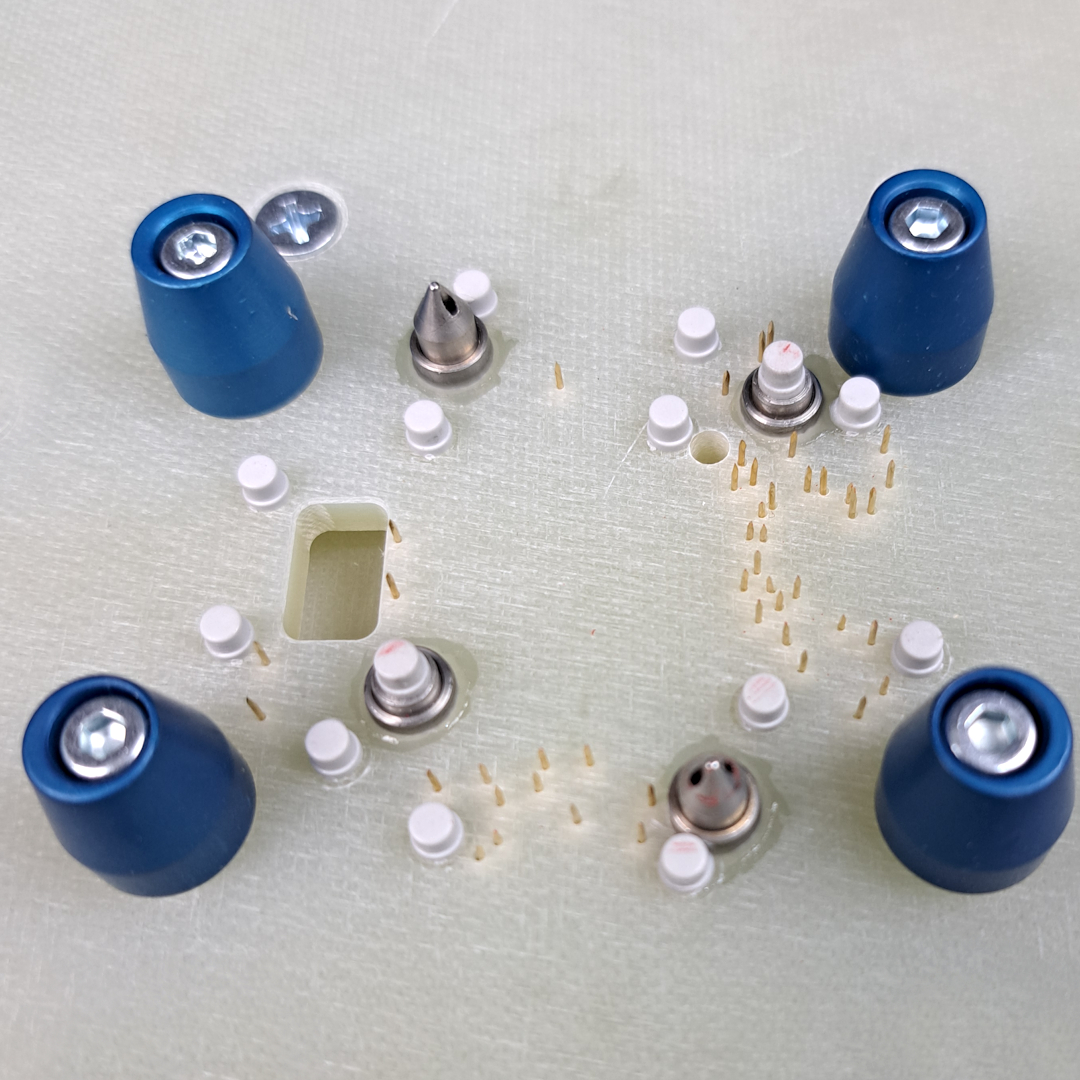

- Pins: To ensure maximum deflection and precision when contacting test points, 95 mm long pins were used. These allow for a deep, stable contact, even at full deflection.

- Rigid pin interchangeable cassette: The rigid pin cassette was designed to be flexible and durable.

- Combined with vacuum fixture: The system is integrated with a vacuum fixture, optimizing performance and versatility.